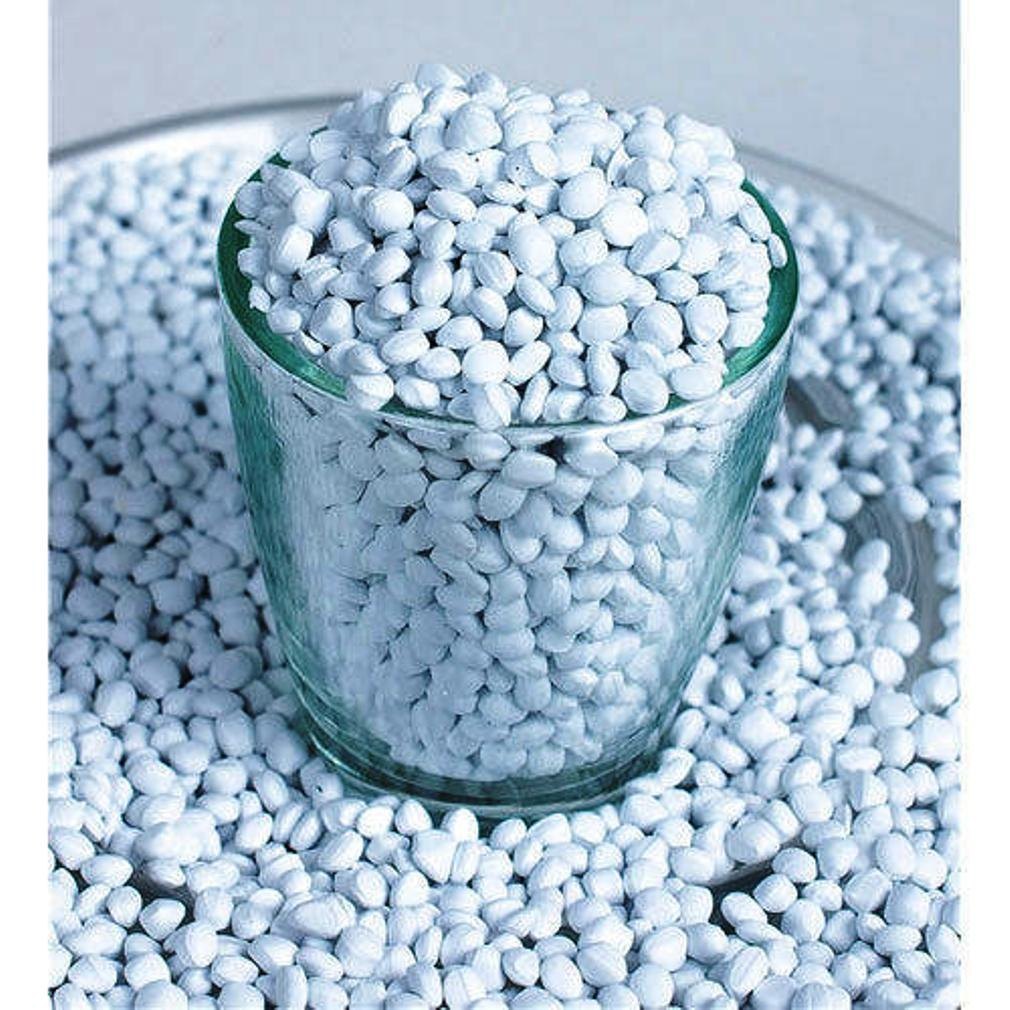

High-Quality White Masterbatches

At Kumar Enterprises, we specialize in producing high-quality white masterbatches that deliver outstanding opacity, brightness, and consistency for a variety of applications. Our white masterbatches are formulated with premium-grade titanium dioxide (TiO2) and other carefully selected additives to ensure superior performance in your products.

Key Benefits of Our White Masterbatches:

Exceptional Whiteness: Our white masterbatches provide brilliant white coloration with excellent dispersion, ensuring uniformity across all applications.

High Opacity: Designed to offer superior coverage, our white masterbatches effectively mask the base color of your materials, resulting in a clean, bright finish.

UV Protection: Enhanced with UV stabilizers, our white masterbatches help protect your products from UV degradation, extending their lifespan and maintaining their appearance.

Versatile Applications: Suitable for use in a wide range of industries, including packaging, automotive, construction, and consumer goods.

Custom Formulations: We offer customized white masterbatch solutions to meet specific processing requirements and achieve the desired optical properties in your products.

What is White Masterbatch

A white masterbatch is a concentrated mixture of pigments and additives encapsulated in a carrier resin, typically used to impart white coloration to plastic products. The primary pigment used in white masterbatch is titanium dioxide (TiO2), which is known for its excellent opacity, brightness, and UV resistance.

Key Functions of White Masterbatch:

- Coloration: White masterbatch is used to provide a uniform white color to plastic materials, ensuring that the end products have consistent and vibrant whiteness.

- Opacity: It enhances the opacity of the plastic, making it ideal for applications where light-blocking properties are needed, such as in packaging.

- UV Protection: The TiO2 in white masterbatch also offers UV protection, which helps in extending the life of the plastic product by preventing degradation caused by sunlight.

Why do Businesses need white plastic masterbatch?

Businesses need white plastic masterbatch for several important reasons:

1. Consistent and High-Quality Coloration

- Uniform Appearance: White masterbatch ensures a consistent and uniform white color across all plastic products, which is crucial for maintaining brand consistency and product appeal.

- Brightness and Opacity: It provides high levels of brightness and opacity, making the product look more attractive and ensuring that underlying materials or defects are not visible.

2. UV Protection

- Enhanced Durability: The titanium dioxide (TiO2) in white masterbatch offers UV resistance, protecting plastic products from degradation caused by sunlight exposure. This is particularly important for outdoor applications, such as construction materials or outdoor furniture.

3. Cost Efficiency

- Optimized Production: Using white masterbatch allows businesses to efficiently produce large volumes of white-colored plastic products without the need to purchase and handle raw pigments separately.

- Reduced Waste: The use of masterbatch reduces the risk of color inconsistencies and defects, thereby minimizing waste and production costs.

4. Versatility in Applications

- Wide Range of Uses: White masterbatch is used in various industries, including packaging, automotive, consumer goods, and construction. Its versatility makes it a valuable resource for businesses across different sectors.

- Customization: Businesses can customize white masterbatch formulations to meet specific performance requirements, such as enhanced UV stability or specific processing needs.

5. Sustainability

- Eco-Friendly Options: Many white masterbatches are formulated to be more environmentally friendly, with options that support recycling or use biodegradable components. This helps businesses meet sustainability goals and regulatory requirements.

By using white plastic masterbatch, businesses can achieve high-quality, durable, and aesthetically pleasing products while optimizing production processes and meeting industry standards.

Request a Quote Now !

Request a quote today to place your order promptly and avoid any unnecessary delays.

If you have any questions, feel free to call or drop us a message.